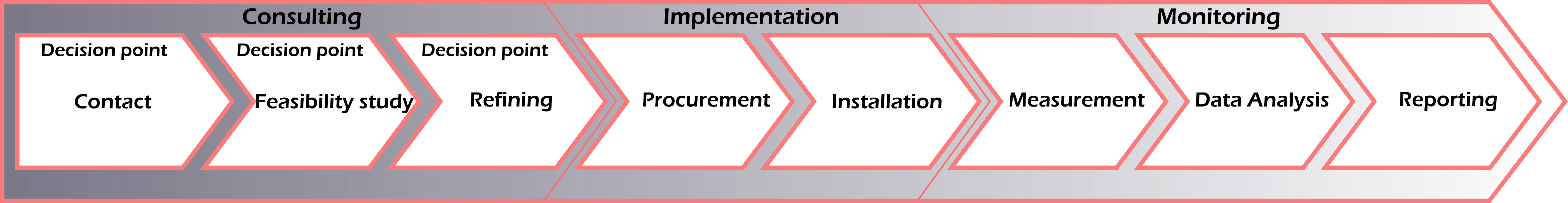

Our service

Phase 1: Contact

Most people are familiar with fiber optics when it comes to fast and modern Internet. However, even standard telecommunications fibers can achieve much more than just transmitting data from A to B. For example, the installed optical fiber itself can be used as a distributed sensor chain to collect accurate measurements of temperature, acoustics and even static deformation along the entire length of the cable. Contact us now to learn all about this state-of-the-art technology and your personal application potential.

Phase 2: Feasibility study

As convinced as we are of our measurement technology, we are well aware that cost-effectiveness is the central argument for deciding whether a fiber optic monitoring system is suitable for your technical application. Based on your requirements profile and your wishes, we will develop implementation strategies that are a perfect fit for you.

Phase 3: Refinement

In this phase, a detailed elaboration of the monitoring concept is created. Based on your technical requirements, we develop the optimal concept. This includes suitable sensor cables, optimal measuring devices and a smooth cable installation and monitoring process. The key questions here are:

What is the geometry of the measuring section?

How is the measuring section implemented?

At which locations are which measured variables relevant?

What is the desired spatial and temporal resolution?

Should the data be retrievable in real time or subsequently processed?

Our target: maximum added value at minimum cost.

Phase 4: Procurement

For most installation projects, we are able to quickly provide the necessary material items through our own inventory (measuring devices, measuring cables). If your project has special requirements (thermal, mechanical or chemical), you can benefit from our international network of specialists in the field of fiber optic sensor technology and measuring cable manufacturing.

Phase 5: Installation

Whether in remote geothermal fields in Iceland or existing drilling sites, our team is experienced in the implementation of measurement cables of any kind. We implement your measurement concept, from logistics to successful installation.

Phase 6: Measurement

Through our large pool of measurement devices we detect optionally temperature, strain and acoustics with highest local and temporal resolution and link the results to your operational events. For this purpose, our own software comes to light, which, based on our experience of the last 10 years, is constantly being developed to guarantee maximum efficiency.

Phase 7: Data Analysis

Our FOMON. heart beats for data analysis! The integrated interpretation of fiber optic, spatially distributed temperature, strain and acoustic data provides a unique insight into technical processes and is used by our expertise to accurately determine the state of solid, liquid or gaseous media. We are also experienced in developing analytical and empirical models to validate the measured data and characterize the physical and technical properties of the object under investigation.

Phase 8: Reporting

Thorough reporting is the key to sustainable, technological and business development. The FOMON. team has already played a leading role in a large number of monitoring projects and has written its findings in final technical reports for clients and authorities. We ensure that you will have full insight into the integrity of your technical object both during and after the monitoring campaign.